Superordinate control for hybrid

heating centers and energy stations

With the integration of renewable energies into modern energy stations, the complexity for an economical operation of all existing generators, consumers and storage systems increases significantly.

This is precisely where the SE²MASTER comes in,

the configurable control system for the higher-level control of energy centers.

All types of components, such as heat pumps, CHP units, electrolysers, photovoltaics, biomass, solar thermal energy or geothermal energy as well as electric heaters and gas boilers, but also battery storage or heat storage, network pumps and valves are perfectly controlled like a large orchestra.

Modular, efficient and scalable at any time: from simple central heating systems and innovative CHP systems to complex combined heat and power plants in districts, clinics, swimming halls and in the commercial and industrial sectors. For the reliable supply of local and district heating in heating networks and combined heating networks.

Advantages of our

Energy Stations Control Systems

- Superordinate control of all generators, consumers & auxiliary units

- Efficient configuration instead of conventional programming

- Priority switching for renewable energy or high-efficiency generators

- Dynamic grid compensation for off-peak control

- Central Management for battery or heat storages

- Weather compensated flow control

- Suitable for series production due to high degree of standardization

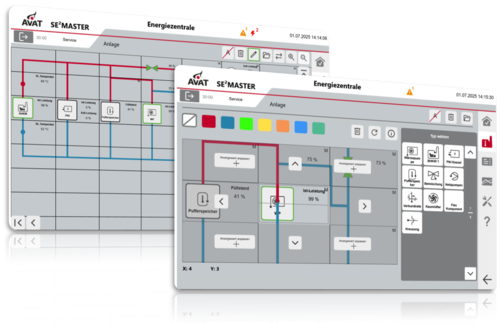

- Clear user interface for the entire energy station

- Direct control and regulation of individual generators and units

- Display of actual values, trend curves and fault messages

- Setting of parameters, setpoints and limit values

- RI diagram can be created in detail according to your preferences

- 10.1" or 15.6" large, capacitive color touch panel

- Administration of user-oriented access authorizations

- Remote access via web browser or classic grid control systems

The service tool

for even more possibilities

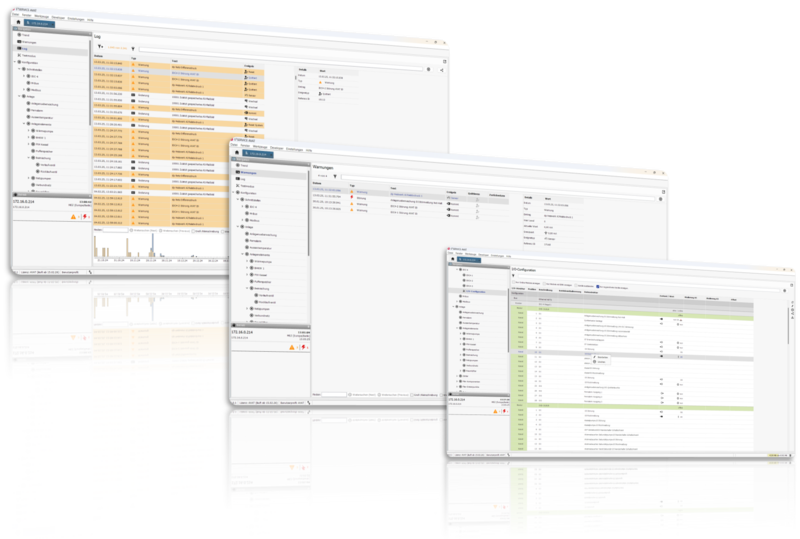

E²SERVICE Energy is the perfect additional tool for even deeper intervention during configuration, maintenance, faults or troubleshooting:

- Clear overviews of the unit status including all measured values

- Reconfiguration of the system elements and IO levels

- Electronic operating log as an event log

(incl. all messages, alarms, acknowledgements) - Combined views of parameters, data curves and characteristic maps

- Control of all signaling or actuating devices by means of testing or activation

- Snapshot function for saving the complete "live" status information

Plant components

- Interface for up to 60 M-Bus meters

- The standard version includes a variety of digital and analog inputs and outputs (0-10V and 4-20mA)

Alerting

Configurable output via digital outputs or via control system interface

Grid Control

Modbus-TCP

Plant Optimization

Modbus-TCP

Software Updates

Via USB or Ethernet

From concept to turnkey Energy Stations in just a few standardized steps

Our solution for the higher-level control of energy centers follows a consistently standardized and modular approach. This also applies from planning to seamless commissioning. This minimizes the project effort and significantly shortens the time-to-operation.

Our process - fully automated:

1. RI Scheme

Basis for designing the system and defining the control strategy.

2. Component list

Automatically generated parts list with all control and field devices.

3. Circuit diagram

Creation of circuit diagrams based on standardized templates and function blocks.

4. Configuration

Parameterization of the control strategy, automated I/O assignment and device communication with preconfigured modules.

5. Commissioning & Live Operation

Fast start-up of the system with tested standard logic.

6. OPTIONAL: Transfer to the SE2OPERATOR Grid Control System

Automatic connection of visualization and configuration to the heat grid control system.

Integration into the overall cross-sector system

Heat Grid Control System >>> SE²OPERATOR

The SE²OPERATOR is AVAT's digital heat control system for the reliable supply of individual heating networks or complex composite heating systems. It visualizes the entire network, from the energy centers to all transition stations, and enables the control, monitoring and optimization of all operating processes, including remote access.

Transfer of the configuration data via standardized interface (Modbus-TCP) for direct, fast and efficient connection:

- The entire data model of the SE²MASTER is automatically read out, transferred and created in the grid control system

- Transfer of the visualization of the hydraulic diagram with operating level of all units, measured values and setpoint specifications

- Transfer of the monitoring functions: Setting of 24-hour trend curves as well as fault and operating messages

Energy Station Optimiziation >>> SE²OPTIMIZER

Integration of the schedule data generated by optimizing the entire system. AVAT's SE²OPTIMIZER, our AI-based energy station optimizer that automatically determines the flexibility potential of generators, consumers and storage systems in energy systems, is connected directly via a standardized interface (Modbus RTU). Taking into account system-specific requirements and regulatory specifications, the operating mode of the system is controlled in a targeted and price-oriented manner, always with a view to the use of own electricity as well as procurement and feed-in on the electricity stock exchange.

We support you in all aspects of planning and commissioning:

- Energy station planning

- Functional description

- Interface test on site

- System parameterization

- Operating and monitoring functionalities

- Complete configuration of all interfaces

- Visualization of the hydraulic diagram

- Setting of trend curves

- Setting of fault and operating messages

- Installation tested ready for operation

- System documentation

- Training of operating personnel and service staff

- Connection to existing control technology

- Integration of AI forecast-based system optimization

- Connection to a virtual power plant

![[Translate to English:] AVAT SE²MASTER übergeordnete Regelung hybrider Energiezentralen und Heizzentralen [Translate to English:] AVAT SE²MASTER übergeordnete Regelung hybrider Energiezentralen und Heizzentralen](/fileadmin/_processed_/4/9/csm_AVAT_SE2MASTER_Energiezentralenregelung_Visualisierung_Dashboards_cc74dbb42a.png)