Economic plant optimization

with AI forecast-based schedule generation

Fully automated reduction of power costs and generation of additional revenue by means of cost-optimized schedules for the entire system operation based on extensive forecasting algorithms in compliance with operational framework conditions.

The key words are: intelligent optimization and long-term profit.

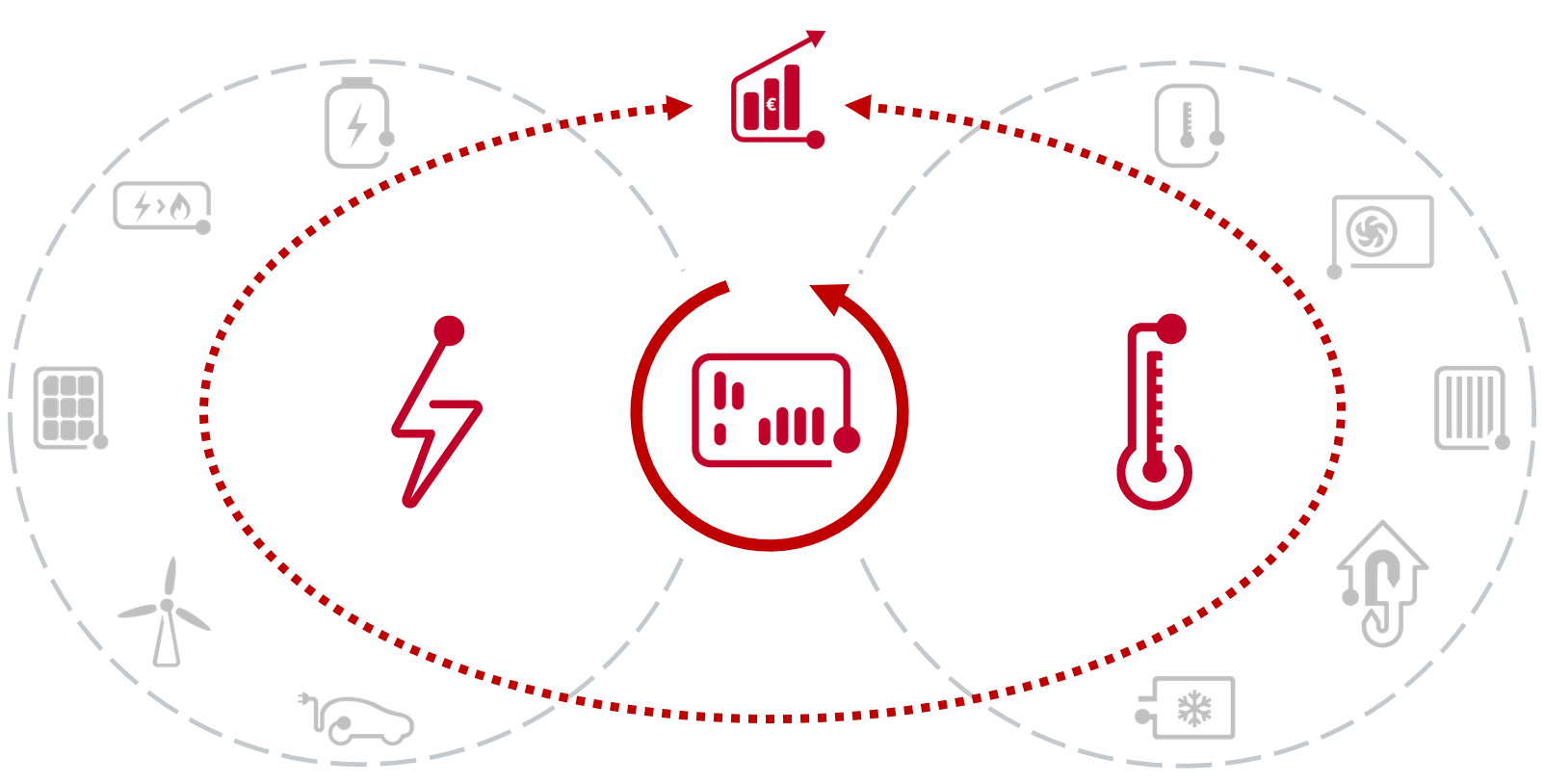

The solution: AVAT SE²OPTIMIZER

The AVAT SE²OPTIMIZER enables the fully automatic control of generators, consumers and storage systems with flexibility potential. The intelligent energy management system optimizes the operating mode in a targeted market price-oriented manner - with a view to own electricity use as well as procurement and feed-in on the electricity markets - taking into account system-specific flexibilities, requirements and regulatory specifications.

Advantages of our

fully automated optimization

- Reduction of electricity and heat generation costs

- Procurement on the forward, day-ahead and intraday markets (IDA/IDC)

- Trading flexibility from CHP and storage across sectors

- Own power optimization by means of load management and own use

- Continuous reaction to intraday deviations on the intraday (smoothing)

- Reduction of the risk of balancing energy costs

All systems can remain in their own balancing group and trading access and the direct marketer can be freely selected at any time.

One solution with many areas of application

Flexible connection of a wide range of system types and application areas

Energy Plants

Minimizing production costs while complying with the energy mix requirements for the supply of heating networks and connections.

Industrial Plants

Own use of electricity, variable grid charges, atypical grid use and limitation of power and gas procurement and feed-in.

Wind & Solar Parks

Price-controlled feed-in, careful use of battery storage or multi-use for own electricity, peak shaving and electricity trading.

Biogas Plants

Power price-based operation of overbuilt systems with optimized start-stop cycles, gas forecasting, storage and fermenter management.

Boiler Units

Demand-based and economical use with negative electricity prices.

Heat Pumps

Temperature-dependent generation output & power consumption.

Industrial Chillers

Energy cost-optimized control, timing and storage management.

E-Charging

Dynamic load management to avoid grid expansion.

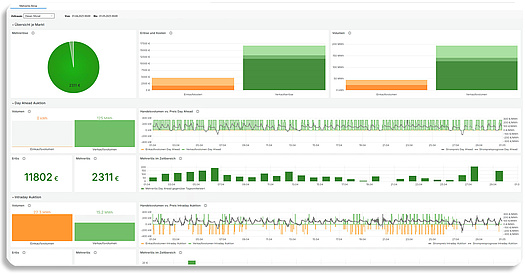

SE²OPTIMIZER Cockpit

Maximum transparency and control for energy plants: The SE²OPTIMIZER Cockpit offers an interactive, user-friendly interface for monitoring, controlling and optimizing energy generation facilities - in real time and in retrospect.

- Visualization of the digital twin of the energy plants

- Configuration and parameterization of the system structure

- Manual control including live interventions in operation

- Dashboards for revenue, operating data and regulatory requirements

- Insight into all planning and optimization of schedules

- Standardized dashboards for operation and trading as shared basis

- Presentation of forecast and realized additional revenue per market

The operating personnel maintain an overview of the current system status at all times, understand the ongoing optimizations and can intervene manually if necessary. Historical data enables complete tracking of system operation.

The forecasts are created on the basis of various data models and are based on machine learning (AI). Numerous forecasting modules are already available in various sectors for the targeted optimization goals in order to create schedules in compliance with the framework and boundary conditions:

Load and consumption forecasts

Heat demand forecasts for districts, local heating networks, district heating network connections, process heat, etc.

Power consumption forecasts

Electricity demand of neighborhoods, factory electricity, charging stations or large industrial electricity consumers

Gas production forecasts

Biogas generation and use at a biogas plant (Nawaro / from organic waste)

PV generation forecasts

For integrated PV systems (behind the meter) or from large ground-mounted or rooftop systems (front of the meter)

Weather forecasts

- Temperature forecasts > for heat supply in heating networks and heating network connections

- Wind forecasts > for integrated wind turbines (behind the meter) or a wind farm (front of the meter)

- Cloud cover forecasts > for integrated PV systems (behind the meter) or for ground-mounted or roof-mounted systems (front of the meter)

Exchange price forecasts

Development of expected prices on the spot market

All optimization targets can be based on fixed boundary conditions as a set of rules.

Possible economic framework conditions

- Joint operation in accordance with EEG 2021 (joint operation of two CHP units with 4000 ¼ hours simultaneously)

- Compliance with electricity purchase/feed-in limits to reduce the power price

- CHP minimum share

- Compliance with maximum number of starts, e.g. of CHP units to reduce maintenance costs and compliance with the maintenance contract

- Compliance with maximum number of battery cycles to ensure a long service life

- Alignment of operating hours, e.g. several CHP units for uniform use and uniform maintenance intervals

- Compliance with iKWK requirements to maintain at least 30% heat generation with renewable generators

Possible technical framework conditions

- Live monitoring of temperature limit values or storage tank fill levels to ensure the heat supply

- Compliance with minimum operating times/minimum downtimes

- Compliance with maximum output values for heat exchangers etc.

- Automatic selection of the best individual forecast from the various methods

- Reduction in electricity output price through forecast-based peak shaving

- Integration of time-dependent electricity and gas tariffs

- Overall optimization of several systems: Aggregation of trading volumes, e.g. per direct marketer and market (AVAT SE²DIRECTOR)

Modbus-TCP or Profibus-DP

- A Modbus-TCP or Profibus-DP

Master interface is added to the system controller by the customer in accordance with the AVAT data point list so that the SE²OPTIMIZER receives the data required for optimization from the system and can control the subsystems. - AVAT CLOUD communication interface

Connection via VPN router via LAN or WAN. The technical system data is sent exclusively anonymously to the AVAT Cloud for monitoring the forecast and revenue quality.

Decentralized or centralized, ... it doesn't matter, both are possible

Data sovereignty and intervention options remain 100% with the operator and within the systems. The high level of security and process speed ensures automated system optimization both for on-site installation and SaaS applications.

- Decentralized

Industrial PC on site, in the system cabinet, including data storage. - Centralized

On-premise, as a pure software solution on the customer's own server.

Connection to the overall cross-sector system

Connection to the energy station control system SE²MASTER

Simple connection of up to 100 subsystems, such as generators, storage units and consumers.

Connection to the heat grid control system SE²OPERATOR

A direct, fast and efficient connection is possible via a standardized interface to the SE²OPERATOR.

- Data model of the data logger is automatically read out and transferred

- Data points are automatically created in the control system

- Scalable at any time according to the required number of data loggers

Our current compensation models

- Fixed performance remuneration (annual)

- Optimization support fixed (24 months)

- Variable revenue sharing (24 months)

Our basic support for system optimization includes

- Automated creation and delivery of schedules during the runtime

- Monitoring the optimization with regard to schedule adherence and system status

- Creation of monthly reports

- oftware updates of new releases

We support you in all aspects of optimization with comprehensive carefree support

- Free potential assessment

- Technical coordination

- Suitability test

- Flex Check

- On-site inventory

- Simulation

- Planning

- Creation of the system model

- Configuration and system parameterization

- Setting up an interface

- Operating and monitoring functionalities

- Functional description

- On-site installation or remote support

- On-site commissioning or remote support

- Establishing and checking remote controllability

- System training with instruction in the cockpit