Still at university Frank Ganssloser opens his engineering office as a one-man operation. In the first years he is very productive and developes the first start / stop control with monitoring functions of gas engines in 1989.

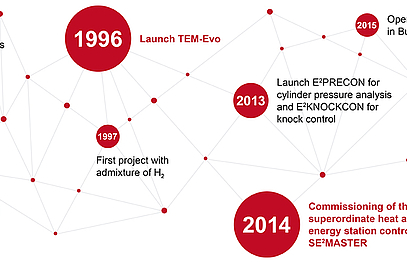

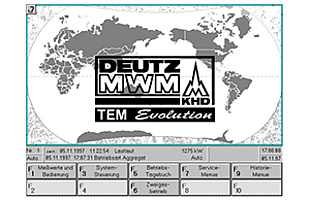

The control of gas engines is revolutionized: As the world's first, digital and integrated automation system for gas engines, the TEM system developed by Mr Ganssloser convinces MWM, one of the world's leading gas engine manufacturers, to implement the control system as standard on the engine series TBG 616, 620 and 632 as well as TCG 2016, 2020 and 2032.

AVAT Automation GmbH is born. Mr Ganssloser and his team do not want to confine to engineering services, but to produce the developed systems themselves. Right from the start, the company causes a stir in the industry when it presents the first remote access to gas engine control via modem.

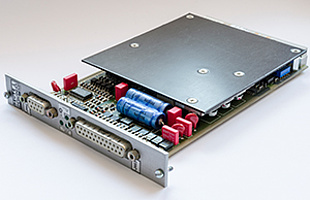

With the development of the speed controller card SERV and the stepper motor card STEP, AVAT can now deliver software, hardware and control cabinets from its own production.

In May 1996, the first system with the new TEM-Evolution controller goes into operation and initiates a tremendous success story. For more than 10 years, the system sets the benchmark in the gas engine industry in terms of performance, functionality and service friendliness. AVAT is now responsible for the entire system from the cable to the user interface. The newly developed hardware modules for speed and mixture control, remote fieldbus IO for the auxiliary units, fully integrated anti-knock control and an operator terminal with color display and extensive diagnostic functions delight the users.

Special order from a large Italian coking plant: The sloping coking oven gas is to be converted into electricity in highly efficient gas engines. Several engine manufacturers decline, but MWM and AVAT face the challenge of processing the highly flammable gas with 50% hydrogen content. Our engineers take full advantage of the fully integrated TEM-Evolution system and program completely new operations and protection functions to control the 9 motors with a total of 25 MW of power. The plant ensures the economic operation of the entire coking plant to this day.

Long before big data is on everyone's lips, the RMS Remote Monitoring System continuously collects data from all connected systems and automatically alerts service personnel in the event of a fault. Customers are skeptical about the benefits. We were probably too early.

For the Deutz engines of the 1015 series with 180 kW and 240 kW power, AVAT develops a new, compact motor control: TEM Basic. Four weeks after the order, a prototype system is available. Within 15 months, our team develops parallel production-ready hardware, software and documentation. Particularly innovative are the misfire detection from the ongoing analysis of the speed curve and a cylinder-specific anti-knock control with an extremely favorable ignition system.

AVAT speakers are now being asked to present at conferences. At the Large Engine TechDays, the diesel industry is still debating whether electronics on the engine are a curse or a blessing. Our lecture titled "Electronic Controls on Large Gas Engines - Design Potentials and Concerns" shows that this question has long since been decided and opens up completely new possibilities for engine operation and user interaction. In order not to scare the conservative audience, we also talk about electronics on the engine. Of course, the main challenges and opportunities are in the software.

With Smart E²CON, we are launching a compact controller that has been significantly expanded compared to the TEM Basic. Smart E²CON is used by several customers in Asia.

OMV Petrom invites us to Constanta, Romania, where the company is building a decentralized power generation station for the self-sufficient power supply of a natural gas refinery. 5 gas engines from MWM, each with 2 MW electrical power, run on island operation with power stabilizer, emergency diesel and a high-performance unit for uninterruptible power supply. In order to connect the individual components to the refinery, we are to integrate fully redundant power management. We deliver reliably and add a year later at the "PetromCity" headquarters in Budapest. In addition to the power management, the energy center also receives a higher-level load management, which shuts off individual consumers when the network is overloaded.

The new model-based TEM-evo multivariable controller for speed, power and mixture drives the welding beads on the forehead with the extremely fast load ramps that are possible with it. For the service technicians in the field eliminates the tedious controller fine tuning. Almost all motors are operated with the factory settings of the robust controller.

E²PRECON-M and E²KNOCKCON-M are the first AVAT devices with Marine Type Approval on the market. The audits of the classification societies certify exemplary development and production processes. Especially the cylinder pressure analysis with E²PRECON-M meets the growing demand for operational optimization and condition monitoring in the marine sector.

129.0756416 / 35.1795543: This is Busan, South Korea, home to our new Asian subsidiary AVAT Asia Pacific. On the 14th floor our colleagues look directly at the port and the cargo ships of our customers. An important step towards internationalization.

Pointing the way is the system kit openECS (Engine Control System). With the open and flexible hardware and software components, both the motor and the entire periphery can be safely and flexibly controlled and monitored with just one controller.

We celebrate 25 years of AVAT.

For the first time we deploy our AI-based solution for the intelligent optimization of energy generation plants SE²OPTIMIZER on a farm. Based on weather and electricity price forecasts, the SE²OPTIMIZER controls not only three CHP units with a total output of 1 MW on the farm premises, but also another 250 kW satellite CHP unit in the center of a nearby village - fully automated. The regeneratively generated electricity is profitably marketed in the virtual power plant. In addition, two local heating networks and thus 110 households are supplied with sustainable heat.

2016 and 2021 - once again we are assisting the municipal utilities of Ludwigsburg with the completion of the largest ground-mounted solar thermal plant in Germany and integrating the plant into the citys heating network. The plant, which is being subsidized by the federal government to the tune of almost €10 million, took 3 years to build. A mammoth project with 14,800 m2 of collector surface, 2,000 m3 of thermal storage and 5 km of new district heating pipelines.