AVAT E²CON

Indepentent Control System

already fits all engines and CHP-applications

The development of new engine controllers is our daily business. With experience as a developer and manufacturer of the TEM-Evo control system for MWM gas engines - deployed in thousands of cogeneration plants - and more than 15,000 custom engine controllers, we are confident we can provide the best solution for your needs. For over 30 years, thus we have partnered world-leading manufacturers of gas engines, packagers and plant engineers. In doing so we support our clients with practical experience in all the phases of the project for as long as it takes to reach a plant's design Goals.

The advantages of our solution

One System fits all

With our construction kit principle with a single concept you can implement control from any kind of gas engines, to the generator and the whole auxiliary systems, up to central SCADA systems.

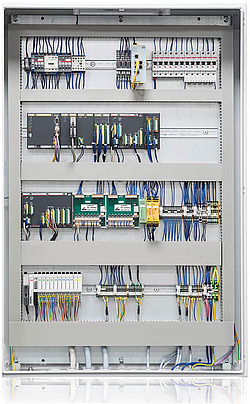

Compact layout

By the use of our compact AVAT Technology Modules, the space requirement on the mounting plate is reduced by around 50% compared with conventional layouts with the same scope of functions.

Comprehensive diagnostics & maintenance tool

Our service software E²SERVICE is the perfect tool to keep track of all challenges during commissioning, maintenance, troubleshooting or daily operation. With our pre-configured AVAT VPN-ROUTERN and AVAT CONNECT, we establish the direct connection from anywhere to the plant securely and quickly.

Comprehensive scope-of-supply

The AVAT Applications are delivered with all circuit diagrams, installation instructions, descriptions of functional characteristics and parameters, and lists of limit values. EPLAN libraries and complete circuit diagrams are available for all the components applied.

Complete control system

for CHP engines and modules

E²CON-CHP

The flexible system for engine,

generator and all auxiliary units

The further development of gas engines and new cogeneration plant operating concepts demand a flexible engine controller. One that can keep the engine operating safely at the limit of its mechanical performance while at the same time integrating it seamlessly into the cogeneration plant or into a whole network of plants.

Based on our flexiblehardware and software components, the E²CON-CHP creates a control system for the entire CHP modules including the gas engine. For typical applications we already have tried-and-tested configurations - from circuit drawings to system visualization.

With our modular principle, you implement the control for engine, generator and auxiliary units up to central SCADA systems with just one concept. Ultimately, you decide what we deliver: The standard application or a solution ready adapted to your requirements, on which our or your developers can continue to work.

Advantages AVAT E²CON-CHP

- E²CON-TE fits all TEM-Evo versions from 1996 to today

- One control system for both the engine and the CHP modules

- Direct NOx control application, including cloud monitoring, for ensuring

compliance with the emission limits set by the 44th BImSchV - Very fast and robust multi-variable closed-loop controller

- Rapid engine run-up to operating speed for a flexible operation

- Wastegate control for improved efficiency

- Grid protection

- Flexibly expandable and adaptable at all time

- H2-ready for future hydrogen applications up to 100%

Certification: For the use of E²CON-CHP according to VDE-AR-N 4110 (TCR Medium Voltage) Code of Practice, a certificate is available. Request our list of certified combinations of gas engines, generators and electronic components already certified with E²CON-CHP. If our already certified modules do not cover your requirements, our modular TCR certificate at a fixed price will help you – contact us now!

The "Technical Connection Rules Medium Voltage" VDE-AR-N 4110 (TCR Medium Voltage) Code of Practice, defines the requirements for energy systems at this voltage level. Manufacturers have to comply these technically binding standards in Europe in order to enhace the energy plants and grids in the long term.

- Closed-loop control of engine speed, power and air/gas mixture via a single, robust and fast multi-variable controller

- Start/Stop sequences for island and grid-parallel operation

- Wastegate control and ignition management

- High selectivity knock control of individual cylinders

- Misfire detection with automatic power reduction downto engine shutdown

- Monitoring of all sensors and measured values

- CAN connection to the ignition system

- Cogeneration plant control (peripherals)

- Closed-loop control and monitoring of all cooling andheating circuits

- Fan control for dry and hybrid coolers

- Control of flow-side temperature even in part load operation

- Premix, lean burn gas engines from

MAN, Liebherr, MTU, Perkins, Caterpillar, etc. - 250 to 2000 kW output range

- 4 to 20 cylinders

- Natural gas, biogas, wooden gas or special gases as well as hydrogen (H2)

- Exhaust gas turbocharger with option of wastegate actuation

- Central venturi gas mixer with stepper motor control

- High voltage capacitor ignition systems

- Two-stage intercooler

- Stationary cogeneration plant applications

- Containerized system or installation in permanent structures

- Engine cooling circuit with emergency cooling via dry cooler

- Intercooler circuit with dry cooler

- Heat extraction via engine coolant and exhaust gas heat exchanger

- Synchronous AC generator, low or medium voltage

- Grid code compliance

MWM / Deutz Retrofit

engine control system

E²CON-TE

Familiar system

with latest state of technology

With the experience we gained on well over 15,000 engine controllers for DEUTZ and MWM gas engines, we are confident we have designed the optimum solution for their modernisation. Taking current needs into account and anticipating future challenges. This new engine management system is based on the lastest technology, and is conceived as a risk-free conversion for replacing the TEM-Evo controllers that were delivered as standard equipment on DEUTZ and MWM engines.

New plant concepts and operating modes demand a flexible engine control system that on the one hand can manage operation at the engine's mechanical limits and on the other hand enables an engine to be quickly and simply adapted to new requirements.

Advantages AVAT E²CON-TE

- Simple commissioning

TEM-Evo-trained service technicians can exchange the system themselves, commission it and adapt it the plant - Delivery

of a complete scope-of-supply including circuit diagram, installation instructions, functional description, list of limit values and parameter descriptions - Web Interface

to the E²PILOT workstation for direct insight onto the controller from any web-capable client - Optional Connection

to the AVAT VIRTUAL SERVICE CENTER for an overview of all connected plants and to an alarm management system with live status - VHPready

for straightforward integration of the plant into a virtual power plant, without the need for an overriding control system to cover this function

Statement of Conformity: For the use of E²CON-TE according to Code of Practice VDE-AR-N 4110 (TCR Medium Voltage), a certified proof of TEM-Evo equivalence is available.

Modernizations with E²CON-TE do not represent a significant change compared to the MWM series control system. Engines and plants previously controlled by TEM-Evo behave uncritically with regard to the electrical characteristics after retrofitting with E²CON-TE and show the same behaviour with the same parameterisation. With E²CON-TE afterwards is like before - contact us for further information!

Parameter Conversion

The risk-free update is achieved via a unique parameter converter. The system's major control functions, such as start/stop, emissions control and control of peripherals behave the same after the retrofit as they did before. In this way AVAT optimally minimizes the risk that the modernization of a competitor's system could lead to a deterioration in control functions.

Optimised Operation

The familiar operating concept as well as the parameter views are retained. With the new operator interface of E²PILOT, anyone who knows the earlier system will soon be at ease and confident enough to start work. In addition, with E²SERVICE service technicians have available a comprehensive service and diagnostic tool.

- Closed-loop control of engine speed, power and air/gas mixture via a single, robust and fast multi-variable controller

- Faster engine run-up for flexible operation

- Start/Stop sequences for island and grid-parallel Operation

- Wastegate control and ignition management

- High selectivity knock control of individual cylinders

- Misfire detection with automatic power reduction down to engine shutdown

- Cogeneration plant control (peripherals)

- Closed-loop control and monitoring of all cooling and heating circuits

- Fan control for dry and hybrid coolers

- Control of flow-side temperature even in part load operation

Download

Jenbacher Retrofit

engine control system

E²CON-GE

E²CON-GE: The Jenbacher Retrofit for more flexibility and an independent gas engine.

Increasing the efficiency of gas engines in the context of modernization and new cogeneration plant operating concepts demand stable and performance-enhancing components as well as a more open and flexible gas engine control system. One that can keep the engine operating safely at the limit of its mechanical repowered parts while at the same time integrating it seamlessly into the cogeneration plant or into a whole network of plants.

With the Jenbacher engine specialized control system, system upgrades are straightforward while providing more options for your individual specifications.

The tailor-made engine controller for Jenbacher gas engines is a specialized control system which is open for all types of expansion. Functions, modules and subsystems harmonize with a high performance user interface to form a single unit. The application for Jenbacher engines covers all your known requirements.

Advantages AVAT E²CON-GE

- A more flexible control system for performance-enhanced Jenbacher gas engines in the context of plant modernization

- More possibilities to change your engine settings

- Reliable knocking and misfire detection included

- Grid and generator protection on board

- Powerful built-in diagnostic and service tools

- Remote and Smart Services on request

- One system for the engine and the auxiliaries

- Flexibly expandable and adaptable at all times

- Update availability over many years

- Independent and fast service

- Professional support and consulting for plant optimization

- Control of engine speed, power and air/gas mixture

- Start/Stop sequences for island and grid-parallel Operation

- Compressor bypass control and ignition management

- High selectivity knock control of individual cylinders

- Misfire detection with automatic power reduction down to engine shutdown

- Monitoring of all sensors and measured values

- CAN connection to the ignition system

- Cogeneration plant control (peripherals)

- Control and monitoring of all cooling and heating circuits

- Fan control for dry and hybrid coolers

- Control of flow-side temperature even in part load operation

Download

Marine Dual-Fuel & LNG

engine control system

E²CON-M

To meet strict emission limits, shipping industry is turning to gaseous fuels. For the best control of engines in marine propulsion and onboard power generation we support our clients with a full line of vertically integrated control and automation technology solutions including hardware, software and, importantly, expert consulting.

Optimized output and reliability under fluctuating or uncertain gas quality is the essence of gas engine control. It can only happen if the control system is precisely adapted to the engine and application. With E²CON-M you will quickly get the controller you need for marine gas or dual fuel engines. A modular system of proven elements, E²CON-M is highly adaptable. In close cooperation with the client, we can rapidly develop a customized control system for every marine medium-speed engine. The result: maximum performance, efficiency and reliability even under high load and rough conditions.

Advantages AVAT E²CON-M

- A control system for both the engine and the auxiliaries

- Rapid engine run-up to operating speed

- Compact system layout

- Powerful built-in diagnostic tools

- Approved control hardware components

- Flexibly expandable and adaptable at all times

- Spare parts availability over many years

- Proven technologies from the large engine field

- High fuel efficiency at optimum emission levels

- Support for engine type approval process

Safety concept

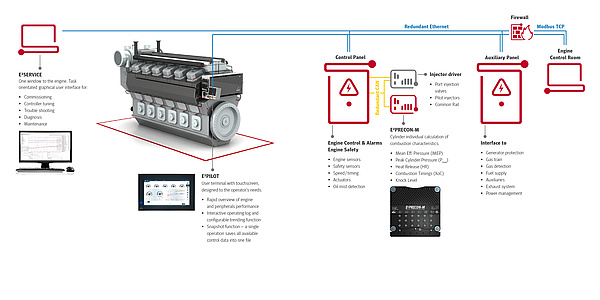

Based on our unique system integration platform for gas and dual fuel engines, E²CON-M is completely flexible, scalable and open to any kind of extension. Functions, modules and subsystems form one unit with a powerful user interface.

E²CON-M is integrated into the ships automation and consists of three units. The control panel with an engine control and alarms module combined with an engine safety system, the auxiliary panel and a technology component to control combustion characteristics. The control architecture is based on an industrial controller. All modules and devices operate according to the principle "smart sensor" and "smart actuator". They deliver pre-processed information and are controlled and configured by the PLC. All control and monitoring functions access the same data and thus all data is usable in the total system and is displayed on the user interface.

The reinforced cabinet of the control panel and the combustion control unit are vibration-damped mounted on the engine. Wiring of sensors and actuators is directly connected to terminal blocks inside the control panel. As third unit the auxiliary panel is placed away from the engine to simplify wiring of auxiliary inputs and outputs. Redundant Ethernet and CAN connections ensure high operational safety.

Functions

- Fuel-sharing mode

- Diesel-gas switchover even at high load operation

- System fulfills requirements for multi engine power generation

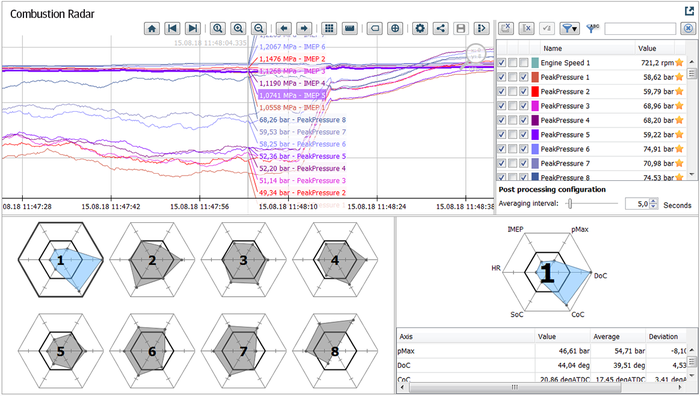

- Cylinder pressure based engine control and monitoring

- Balancing strategies based on identified combustion parameters

- Integrated auxiliary control

- Control and monitoring of fuel supply

- Redundant standard data interface to vessel control

- One powerful remote service tool for direct access to the engine

- Acquisition and processing of relevant KPIs

Marine Type Approvals

Our company's quality management and development processes are subject to external audits on a regular basis. Thus the E²CON-M components are type-approved by major marine classification societies.

With our engine know-how and experience based on years of working and developing together with major engine builders, we are able to fully support our clients in the process of engine type approval and accompany their project from the drawing board to its sea trials.

Service Software

for our control systems

E²SERVICE

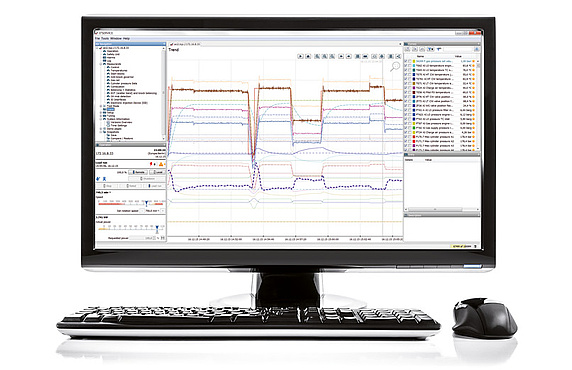

Our service software E²SERVICE is the perfect tool to keep track of all challenges in engine development, on the test bench, during commissioning, maintenance, troubleshooting or simply in safe, daily operation. With E²SERVICE, the data generated during engine operation can be processed for parameter setting and performance improvement.

Advantages of AVAT E²SERVICE

- A compact overview of the genset status with the possibility of manual operation

- Sensibly summarized parameter list for a simplified view

- Electronic operation diary as event log containing all events, messages, alarms or faults, including acknowledgements

- Clear display of all measured values including recording

- Graphical display of data history or trends

- Snapshot for saving the complete "live" status information for e.g. later offline analyses

- Combined views of parameters, data curves and maps

- Parameter comparison and recovery

- Control of signal or actuator devices by manual test or activation

- Search and filter functions for quick selection

- Export of stored data in an open file format

Sales and Service Partners

Trusted partners for your energy are characterized by competence and qualified expertise. Contact our Certified System Partners directly for integral consulting, planning, sales and commisioning as well as maintenance and repair services on site of our products and solutions.

![[Translate to English:] AVAT BHKW Standard Application](/fileadmin/_processed_/3/7/csm_AVAT_BHKW-Standard_Applikation_Schaltschrank_offen_M_a7bc97f41e.jpg)

![[Translate to English:] AVAT Certified System Partner auf einen Blick](/fileadmin/filecontent/99-Bildelemente/CSP/Logo_AVAT_Certified-System-Partner.png)