NOx emissions

AVAT NOx-REGULATION

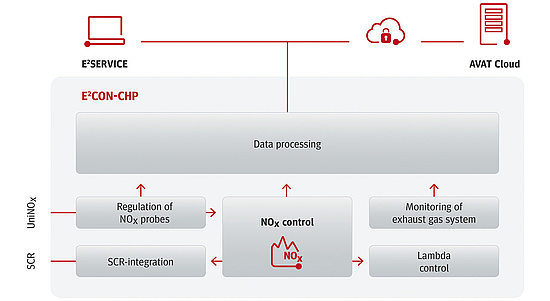

Designed for this very purpose, the AVAT NOx-control is a comprehensive solution that uses the NOx probe connection in the E²CORE-control+ multivariable controller to efficiently regulate the interaction of the engine and the SCR catalytic converter in real time.

Operators of power generation plants with CHP gas engines must now provide sufficient evidence that the legally prescribed limits are being observed. Technically this is usually met through the use of small NOx boxes that continuously measure and record the amount of nitrogen oxide in the exhaust gas.

However, this method alone only solves half the challenge for many plant operators. Simple monitoring does not change the NOx values of the engine. To benefit generators, suppliers, communities and the environment, technical NOx solutions must actively regulate the combustion process to ensure that fewer nitrogen oxides are actually emitted and the prescribed limits are consistently met.

Advantages of the AVAT NOx control

- Direct control, including cloud monitoring

- Lower risk of exceeding NOx limits, which forces operators to intervene or report to authorities

- Reliable engine operation without safety margin from NOx limits for continued high efficiency

- Hybrid control for lean-burn engines with lambda control of NOx values inside the engine and subsequent admixture of AdBlue

Our E²CON-CHP gas engine and CHP control system features the E²CORE-control+ multivariable controller, which is designed to regulate probe operation, process measurement data (30-minute & daily averages) and provide continuous monitoring. Based on operating data from the gas engine and the NOx measurement prior to the SCR catalytic converter, the E²CON-CHP engine control system determines the necessary amount of AdBlue and immediately transfers that amount to the SCR system. This allows the engine to maintain optimal operation in accordance with the preset NOx values. The measurement values of the NOx probe are continuously checked for plausibility. If an engine knock or misfire occurs, the E²CORE-control+ will automatically switch to safe mode without NOx measurement to prevent engine damage.

Control NOx values from anywhere

All NOx and SCR measurements are recorded in the engine operating history, appear in the snapshots from the E²SERVICE software and are available for high-resolution diagnostics from anywhere in the world. To enable this, our E²CON-CHP engine control system transfers the encrypted measurement values to the AVAT CLOUD at regular intervals. If the internet connection fails, unsent data will be transmitted once the connection is restored. If a notifiable event occurs, an e-mail will be automatically sent to the saved address for notification.

In the AVAT CLOUD, data from all connected systems is archived for a minimum of 6 years and can be exported for further processing. The amount of data archived is significantly more than those supplied by many of the NOx boxes currently available on the market. The data is encrypted and password-protected and can be accessed from any computer with an internet connection.

Our cloud dashboard includes

- Plant status in terms of emission compliance

- Complete presentation of all emission-relevant events

- History of logged measurement values by day, week, month and year