Good news for plant engineers and operators of MWM engines: AVAT, the developer and manufacturer of the well-known and proven TEM-Evo control system, is presenting a future-oriented retrofit package. Using E²CON-TE, MWM gas engines can be quickly and safely modernized and efficiently controlled in a familiar application environment.

The new E²CON-TE engine management system is the logical solution for every operator who wishes to make their combined heat and power plant (CHP) fit-for-future - a future in which plants will be expected to respond flexibly to changing demand for electrical power and comply with new conditions for grid connection and grid protection. E²CON-TE is tailored to the updating of MWM gas engines of the Series TBG 616, 620 and 632, and TCG 2016, 2020 and 2032, which can be operated on natural gas, biogas or special gases. The new system comes from AVAT, and thus from the developer and manufacturer of the TEM-Evo control system. The basis of the new E²CON-TE controller is the hardware and software components of the innovative engineering partner's openECS system, which enables the management of virtually any engine and plant.

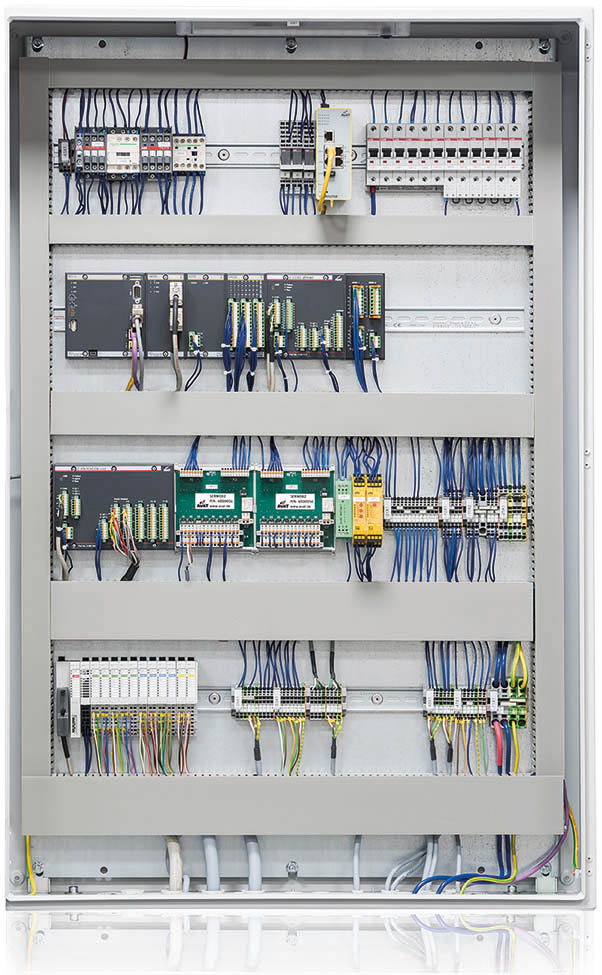

Converting an existing engine to E²CON-TE is straightforward and time-saving, since this retrofit engine controller is conceived as a Plug & Run application. The control cabinet comes ready-configured for immediate installation. All generator-set cables are retained for further use, as are all on-engine actuators. A unique feature of E²CON-TE is its parameter converter. It enables the major existing engine settings such as start/stop, emissions control and control of peripheral devices to be taken over directly by the new control system. Retrofitting E²CON-TE is thus free of the risk that existing control functions could deteriorate.

An operator choosing E²CON-TE will also benefit from its expanded scope for accessing parameters. This opens up new options for individual system adaptations and extensions. In addition, the engine controller is already prepared for the requirements of the VDE 4110 grid connection conditions and the flexible plant operating modes prescribed by BDEW specifications.

In spite of the range of innovations, AVAT's experts have paid special attention to a high level of user comfort in the development of the new engine management system. Accordingly, everyone familiar with TEM-Evo will be able to exchange their system themselves, commission it and adapt it to the engine and plant. The accustomed operating concept and views of measured values and parameters are retained and are clearly laid out in the operator interface of E²PILOT, the intelligent cockpit for the efficient management of the engine and peripherals. Further, with E2SERVICE, service technicians are offered a comprehensive service and diagnostic tool for targeted remote access and safe remote maintenance from any chosen location. State-of-the-art device communication also promises a considerable reduction in workload: Connection to the E2PILOT workstation and the E2SERVICE service tool are ethernet-based throughout. This makes possible their simultaneous use.

Further information here